It is REALLY hard to find an available diesel mechanic these days!

Our poor engine developed an oil leak and it took us over two years to get it fixed.

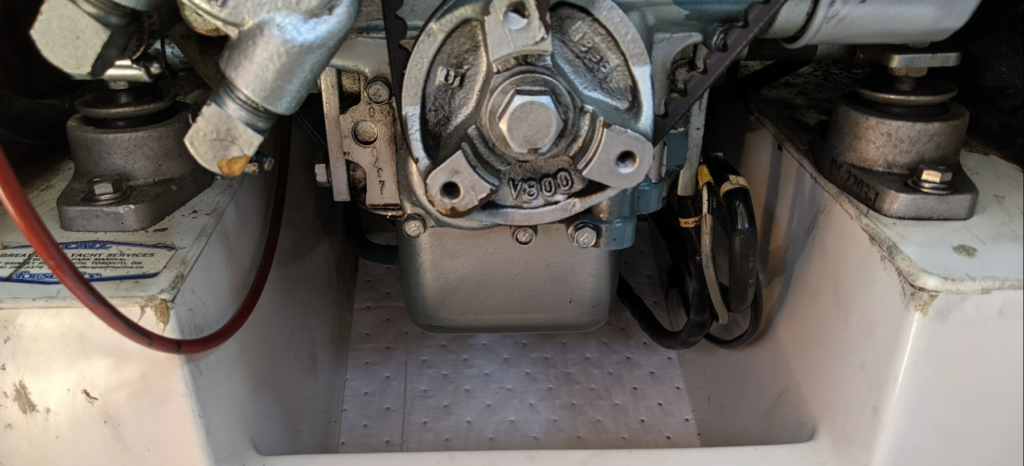

I’m a bit embarrassed by the above photo, we had a slow oil leak that was gradually getting worse. It resulted in us having to stop every 3-4 hours to clean up the engine bilge and replace the oil absorbent pads. I started calling these pads, “engine diapers”.

This all started over two years ago when I realized that finding a diesel mechanic with time to work on your boat is really difficult! I had several contacts in Cobourg that never worked out, they always had other jobs. I then got onto the wait list for the mechanic at Loyalist Cove in August 2020. And of course, Covid threw another wrench into the engine repairs! After getting told numerous times they would get back to me, they finally referred me to another mechanic. In April of this year I get a call from the mechanic, they can work on my boat!

The stuffing box was replaced on the hard and then we were requested to put the boat into the water so the mechanic can run it easier. Foggy was splashed in May.

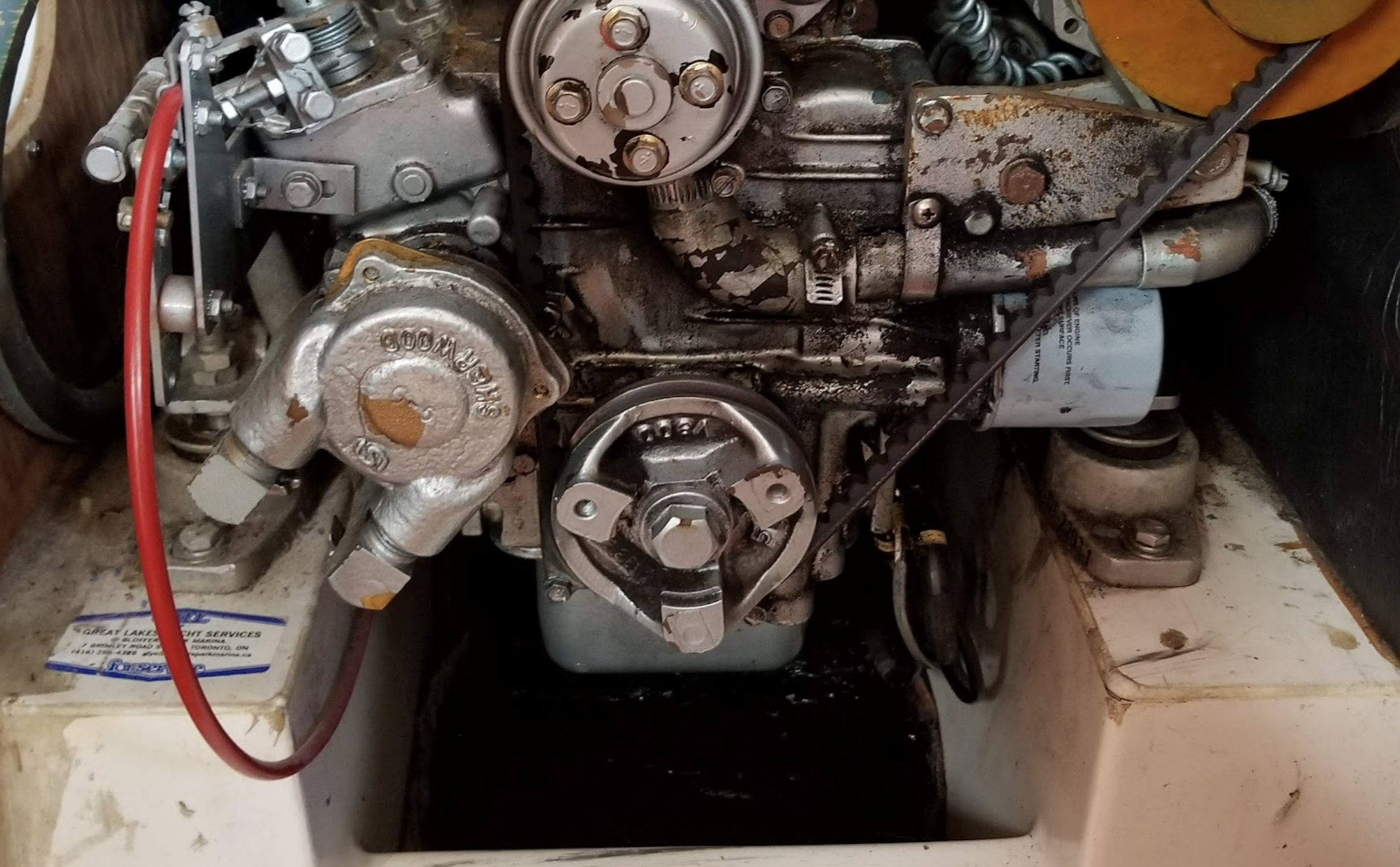

In June, the engine was taken apart and the mechanic found a small leak in our water pump and fixed this for us. The engine was put back together with new gaskets and o-rings that I had purchased six months earlier. At the end of June, we travel out to the boat to check it out, but we find out the leak is still there and also some coolant leaking. The engine needs to be taken apart again, and we need to wait for some parts. It was a sad day.

Ahh well…. we still spent the weekend on the boat, without a mast or motor. But we can’t complain, it’s a beautiful spot. We enjoyed Canada Day at the marina and went up to MacKinnon brewery to watch the Sheep Dogs play.

Despite the waiting, we are still super happy with Loyalist. The staff there are all friendly and helpful. There’s a bit of weed in the area (problem around all of Lake Ontario) but they have been doing a good job cleaning them up. This aerial shot was taken before they cleaned the weeds.

Parts arrive, motor taken apart again and then find out there’s a crack in the casing. This was taken care of extremely fast! Loyalist sent it off to their welder and it was fixed within a day.

End result… on July 28 we were able to motor over to the lift to have our mast stepped. It was a happy day!

Here’s a fun short video of the mast being stepped. Watch carefully, at one point I’m trying to attach the shroud to the wrong side.

We had a bit of extra work getting our new North Sails quick pack installed, I’ll save that for another post. Hint. It didn’t go smoothly, surprise surprise! Lori did have to go up the mast to fix our lazy jacks.

All is good, the engine still has a few minor things that need to be fine tuned but it’s refreshing to be able to open up the engine bay and see the engine diaper without a single drip of oil on it!

The dirty details

Our engine is a 25 hp Universal M4-30 four cylinder diesel engine.

I don’t know exactly where the crack was found, but the highlighted part on the diagram below indicates where I thought the oil was coming from.

The remaining items that need a bit of work:

- Throttle adjustment. It’s running a bit faster at idle than before.

- Throttle cable tension. It slips back to idle too easily. Needs a bit more friction.

- Engine cut off (stop lever) cable adjustment. The T-handle in the cockpit is sticking up 1cm higher than before.

Other than that, she starts up on first press and runs smoothly! The mechanic is going to help me fix these things. With the shortage of diesel mechanics I think it’s good that I start to learn how to do this myself!

August 13, 2022 at 12:00 am

I have an M3-20 universal which is very similar. Yours is super clean!. My fan belt must slap against the water pipe under the alternator. It leaves rubber dust every where in the engine compartment.

I just adjusted the valves on my engine. So far the fuel consumption has been noticeably better. Might want to consider that.

Thx for the posts!

August 13, 2022 at 9:57 am

Thanks Jim! Just starting to learn more about the engine and gaining a bit of confidence with some of the simpler things. I think finding a mechanic is just going to get harder so I guess I need to figure this stuff out myself. I did take some engine mechanics in school, a long time ago!